Track Studding

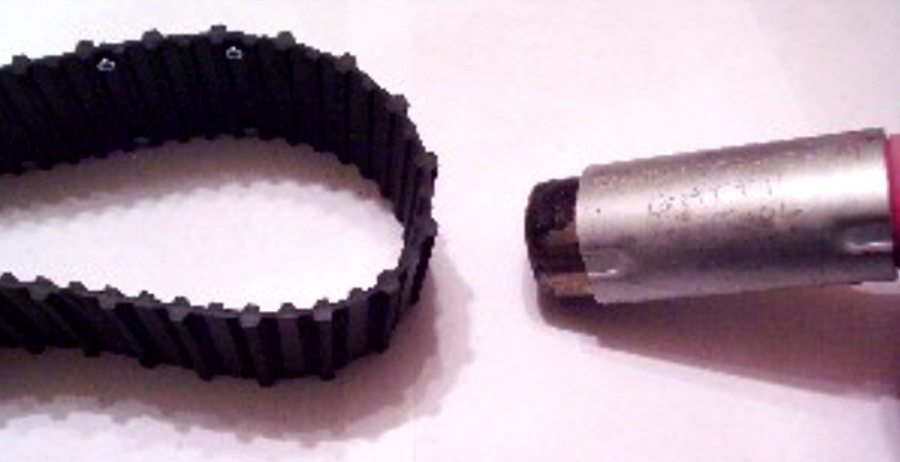

There are many variations of studding, this example is a good one for the stock track supplied in your kit. The suds are No. 4 self tapping screws, phillips pan head, 3/8 “ long. Due to the clearance in your drive sprocket and the rear side Idlers the screws need to be placed 1/4 inch from the edge, minor adjusting may need to be made, since there are many variations of drive sprockets.

Stud screws should be inserted in between the track gearing so they don’t interfere with the idlers and Main track pulley, in most cases these screws will scrape under the tunnel until they clear out a groove. In all case these studs are dangerous when you are running the sled, please do not pick up while the engine or radio are engaged. The use of the studs will save your belt from wearing out, also for street use they will stop the sled from flipping, as they will allow the sled to slide when releasing the throttle.

This type of Track pulley seems to work best, the sides have been cleared for studs and the gearing reduced in width to minimize interference with snow, in all cases use silicone spray on the pulley and all other areas under the suspension to minimize snow collection, keep the suspension clear at all times. Most pulleys can be machined to achieve the same results.

Clutch Overheating

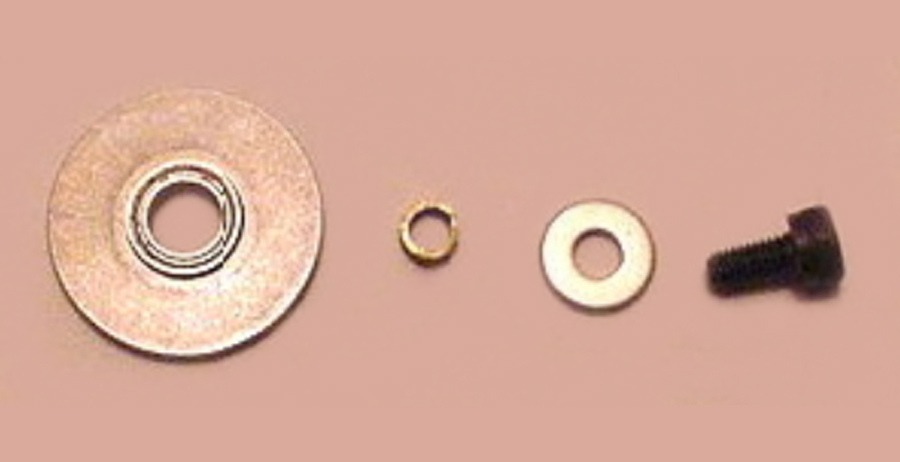

Clutch shoes should be machined to allow the spring to seat lower, thus allowing more life to your clutch system. If the Spring hits the inner clutch bell it will over heat and needs to be replaced.

Due to packaging, the track belts retains an oval shape, using a heat gun, warm the smaller radius until the belt regains a full circle shape. Also check the thin portion of the track, if its more than.100, its too thick, have it replaced.

This is the Colas clutch upgrade, replaces the large washer on the outside of the clutch bell also eliminates the outside bearing inside the bell. The large washer in the stock kit creates heat while rotating, when installed make sure the clutchbell spins freely from the flywheel, the small brass washer is used to eliminate pressure from the 3 mm shcs to the engine shaft.

Belt jumping off the track

There are many reasons that may make the belt jump from the track. Here is the main one. As you insert the rear suspension, check to make sure that there is .005 to .0010 clearance on each side of the belt to clear the rear Idlers. If this area is too tight make sure you have inserted the bearing all the way into the rear side Idlers. If they are you may need to shave the sides of the belt until you have proper clearance. there is a .020 tolerance on the belt. If this is not followed it will cause the track to jump.

Protect your sled

Always keep a bottle of silicone spray on hand. Spray throughly under the track , around all pulleys and idlers and suspension when assembly is completed, let dry. Use once again prior to use. Always keep your suspension free of build up.

Shock trouble

Have you build a shock and it doesn’t return when pressurized. Here’s the little culprit. The flash around the hole on this piece is keeping it tight against the shaft. Remove it with a knife and your trouble will go away.

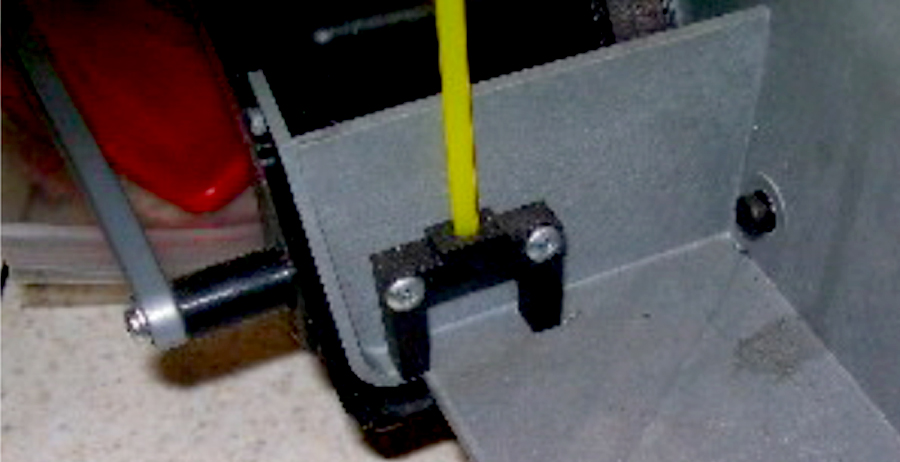

Antenna position

You must keep your antenna away from the electronics and as high as you can. With this set up you should be in control up to 120 yards. Electric Art Attack should keep the antenna in the rear of the sled away from receiver and speed controller.